Particle Size Distribution (PSD) Test

Particle size distribution (PSD) testing is a laboratory method used to determine the distribution of particle sizes in a sample of aggregate. The PSD of an aggregate is an important factor in the performance of construction materials, as it can affect the strength, durability, and workability of the material. PSD tests are usually performed by producers, contractors or independent test laboratories.

Particle size determinations for aggregate samples are crucial to ensure their performance meets their intended use. A gradation test or sieve analysis is conducted to determine the distribution of aggregate particles by size within a given sample. The obtained information is utilized to verify compliance with design and production specifications. Additionally, the data can be employed to comprehend the correlation between aggregates or blends and forecast trends during production.

In PSD testing, a sample of the aggregate is sieved through a series of progressively finer sieves to separate the particles by size. The mass or percentage of the sample that passes through each sieve is then measured and used to calculate the PSD.

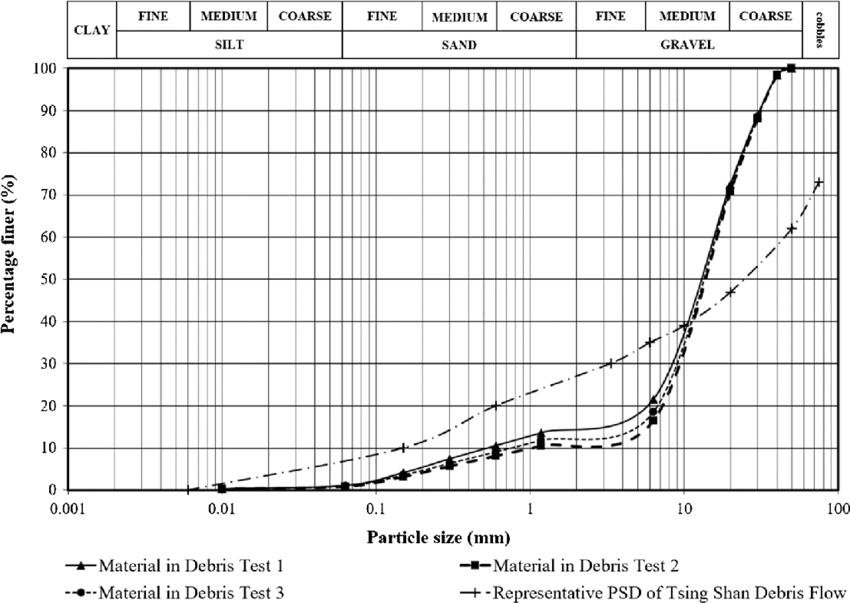

The PSD is typically presented as a graph or chart showing the percentage of the sample by mass that falls within each size range. A gradation test or sieve analysis is conducted to determine the distribution of aggregate particles by size within a given sample. The obtained information is utilized to verify compliance with design and production specifications. Additionally, the data can be employed to comprehend the correlation between aggregates or blends and forecast trends during production.

Apparatus

Sieves

Ovens

Balance

Test Method

The procedure involves placing a predetermined amount of material on top of a series of nested sieves arranged in decreasing size order. The sieves are then mechanically shaken for a specific duration. Upon completion of shaking, the retained material on each sieve is weighed using one of two methods:

Cumulative method - the retained material on each sieve is added to a previously tared pan and weighed. This process continues until all fractions and the bottom pan are added and weighed. This is a quicker option as the pan does not have to be emptied or tared between each fraction.

Fractional method - the contents of each sieve are weighed separately, and the material is discarded only after the entire test is complete.

The technician calculates the percentage of material retained and passing the sieve to the nearest 0.1% by total mass using the following formulas:

Cumulative method - divide the cumulative mass of each retained fraction by the total sample mass and multiply by 100 to calculate percent retained. To calculate percent passing, subtract the cumulative percent retained on a given sieve from 100.

Fractional method - divide the mass retained on each sieve by the total mass and multiply by 100 to calculate percent retained. Percent passing is calculated by subtracting the percent retained on the sieve beneath.

Particle size distribution, or gradation, refers to the dispersion of individual particle sizes throughout the sample. Typically, aggregate gradation is presented graphically on a semi-logarithmic chart by plotting each particle size and drawing a best-fit curve between the points. The full procedure is specified in ASTM C136 (AASHTO T-27) or BS EN 933-2.

Test Report Data (Example)

Associated Tests:

Why is understanding the PSD of aggregate or soil important in construction important?

Understanding the particle size distribution (PSD) of aggregate and soil is crucial for various aspects of construction for several reasons:

Compliance with regional, national, or contract specification

The PSD result is often plotted against graphs to demonstrate compliance with product specifications, e.g. 4/20mm aggregate for use in concrete, SHW Series 600, Sub-base, or contract specific requirements.

Mechanical Strength and Stability

Shear Strength: The particle size affects the shear strength of the soil, which in turn affects the stability of structures built on it.

Load-Bearing Capacity: Knowing the PSD helps engineers assess how well the soil can support the loads imposed by buildings, roads, or other structures.

Hydraulic Properties

Drainage: Soils with different particle sizes have different drainage capabilities, important for avoiding water-logging or soil erosion.

Permeability: The size of particles affects how easily water can flow through soil, which is crucial for managing groundwater and designing effective drainage systems.

Workability

Compaction: The PSD affects how densely the soil or aggregate can be compacted, which is important for road construction, building foundations, and earth dams.

Ease of Mixing: Knowing the PSD can help engineers mix materials more effectively, which is important for concrete and asphalt.

Environmental Considerations

Contaminant Transport: Smaller particles have a higher surface area, affecting how contaminants can move through the soil.

Erosion Control: Understanding particle size helps in designing measures to control erosion, such as selecting the appropriate types of vegetation to plant.

Economic Factors

Resource Optimization: Knowing the PSD can help in selecting the right material for specific purposes, avoiding the costs associated with over-engineering.

Quality Control: PSD analysis is part of the quality checks to ensure that the material being used meets the necessary specifications.

Other Factors

Thermal Properties: Soils with different PSDs have different thermal conductivities, which can be a consideration in some specialized construction scenarios.

Aesthetics: In some cases, the particle size can even affect the final appearance of the construction project, such as in landscaping or decorative stonework.

Understanding these factors allows engineers to make informed decisions about material selection, construction methods, and safety precautions, thereby ensuring the long-term success and stability of construction projects.

Related analysis

Uniformity coefficient

What is uniformity coefficient?

The uniformity coefficient is a measure of the spread or dispersion of the particle sizes in a sample of aggregate. It is calculated from the particle size distribution (PSD) of the aggregate.

The uniformity coefficient is calculated by dividing the difference between the maximum and minimum particle sizes by the mean particle size, or by division of values from pre-selected points on a PSD axis. A high uniformity coefficient indicates that the particle sizes in the sample are widely dispersed, while a low uniformity coefficient indicates that the particle sizes are more uniform or similar in size.

The uniformity coefficient is typically used to assess the suitability of aggregates for use in construction, as well as to control the quality of aggregate products. The uniformity coefficient limit varies based on product type.