Angle of Repose

Understanding Angle of Repose

The angle of repose, also called the critical angle of repose, describes the steepest inclination at which a granular substance can be stacked without collapsing or sliding. It represents the maximum angle of descent or dip relative to the horizontal surface. The range of the angle of repose extends from 0° to 90°. The shape of the material influences this angle, with smooth and rounded sand grains having a lower angle of repose compared to rough and interlocking sands. Additionally, the presence of solvents can affect the angle of repose. If there is a small amount of water that fills the gaps between particles, the electrostatic attraction of the water to mineral surfaces will increase the angle of repose, as well as other related properties such as soil strength.

When bulk granular materials are poured onto a flat surface, they form a conical pile. The angle between the pile's surface and the horizontal plane is known as the angle of repose. This angle depends on factors such as particle density, surface area, shape, and the coefficient of friction of the material. Materials with a low angle of repose create flatter piles, while those with a high angle of repose result in steeper piles.

The term "angle of repose" is also used in mechanics to describe the maximum angle at which an object can remain at rest on an inclined plane without sliding down. This angle is equal to the arctangent of the coefficient of static friction (μs) between the surfaces.

Sand Stockpile (Angle of Repose)

Test Methods

There are various test methods available for determining the angle of repose, and each method yields slightly different results. It's important to note that the exact methodology employed by the experimenter can also influence the results, making data comparison between different laboratories challenging.

Tilting Box Method

This method is suitable for fine-grained, non-cohesive materials consisting of individual particles smaller than 10 mm. The material is placed inside a box with one transparent side to enable observation of the granular test material. Initially, the box should be level and parallel to its base. The box is gradually tilted until the material starts sliding as a bulk, and the angle of the tilt is measured.

Fixed Funnel Method

In this method, the material is poured through a funnel, forming a cone-shaped pile. The tip of the funnel should be held close to the growing cone and slowly raised as the pile accumulates, minimizing the impact of falling particles. Pouring is stopped either when the pile reaches a predetermined height or the base achieves a predetermined width. Instead of directly measuring the angle of the resulting cone, the height is divided by half the width of the base. Taking the inverse tangent of this ratio gives the angle of repose.

Revolving Cylinder Method

The material is placed inside a cylinder with at least one transparent end. The cylinder is rotated at a fixed speed, and the observer watches the movement of the material within the rotating cylinder. This effect is similar to observing clothes tumbling in a slowly rotating clothes dryer. As the granular material flows within the cylinder, it assumes a particular angle. This method is recommended for determining the dynamic angle of repose, which may differ from the static angle of repose obtained using other methods.

Do materials have a typical angle of repose?

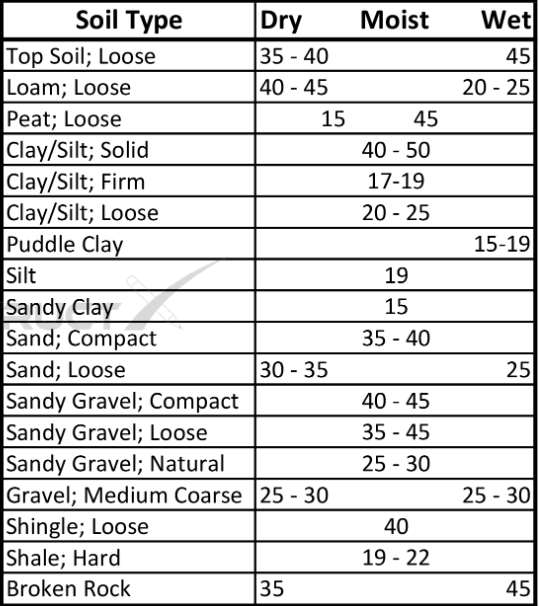

Yes, many materials have a typical angle of repose, which refers to the steepest angle at which a material can be piled or stacked without slumping or collapsing (SEE TABLE BELOW). The angle of repose is influenced by factors such as the shape, size, and surface properties of the particles, as well as the moisture content and other environmental conditions.

Different materials have different angle of repose values. For example:

Granular Materials: Common materials like sand, gravel, rice, and sugar typically have angle of repose values in the range of 25 to 45 degrees.

Fine Powders: Materials like flour, cement, and powdered sugar tend to have lower angle of repose values, often below 30 degrees. This is because fine particles are more prone to cohesion and can form cohesive bridges, leading to shallower angles of repose.

Coarse Grains: Larger particles like rocks and pebbles usually have higher angle of repose values, sometimes exceeding 45 degrees.

Wet Materials: The angle of repose can be significantly affected by moisture content. Wet materials might have angles of repose lower than their dry counterparts due to increased cohesion.

Irregular Shapes: Materials with irregular shapes might not exhibit a consistent angle of repose, as the stacking behavior could be more complex.

Factors Affecting Angle of Repose: In addition to particle size and shape, factors like surface roughness, interparticle friction, and any additives or binders can also influence the angle of repose.

It's important to note that the angle of repose is not a fixed property for a material; it can vary depending on the conditions and methods used for measurement. It's often used in industries such as agriculture, mining, construction, and manufacturing to design efficient storage and handling systems for bulk materials. The only way of finding out what the angle of repose is, is by carrying out a test.

Typical Angle of Repose results

Geotechnical Considerations: Angle of Repose and Slope Stability

The angle of repose plays a crucial role in geotechnics, particularly in the context of slope stability. It is closely linked to the shear strength of geological materials, making it a significant factor in construction and engineering applications. The characteristics of granular materials, such as their size and shape, have a notable influence on the angle of repose. In general, as the grains become rounder, the angle of repose decreases due to reduced inter-grain friction.

Exceeding the angle of repose can lead to mass wasting and rockfall, posing risks to both structures and the natural environment. Civil and geotechnical engineers must have knowledge of the angle of repose to mitigate potential disasters. Implementing retaining walls can effectively prevent the angle of repose from being surpassed, providing stability and soil retention.

It's important to note that the angle of repose and slope stability are influenced by various factors, including climatic and non-climatic conditions. These considerations further underscore the significance of understanding and managing the angle of repose in geotechnical practices.

Angle repose of soil

Factors Affecting Soil Angle of Repose:

Particle Size: Smaller particles often have a higher angle of repose because the increased surface area leads to greater friction, which helps resist sliding.

Moisture Content: The angle of repose can change with the moisture content. Wet soil can have a higher angle of repose because the water holds the particles together. However, if too much water is added, it can reduce the angle of repose as the soil becomes mud or slurry.

Particle Shape: Rounded particles tend to have a lower angle of repose compared to angular particles, as the latter interlock and resist motion.

Angle of Repose for different soil types

Which sectors use angle of repose

The angle of repose is an important concept in various sectors and industries where the flow and stability of granular materials or bulk solids are relevant. Here are some sectors where the angle of repose is significant:

Mining and Quarrying: The angle of repose is crucial in mining and quarrying operations to determine the stability and safe slope angles for excavated materials such as ores, coal, minerals, and aggregates.

Construction and Civil Engineering: In construction, the angle of repose is important for designing slopes, embankments, and retaining walls. It helps engineers understand the stability of soils, rocks, and other granular materials to prevent landslides or collapses.

Agriculture and Food Processing: The angle of repose is relevant in handling and storing agricultural products such as grains, seeds, and powdered substances like flour. It affects the design of silos, hoppers, and conveyor systems used in food processing and storage facilities.

Pharmaceutical and Chemical Industries: Granular materials, powders, and chemicals are often transported, stored, and processed in these industries. Understanding the angle of repose helps in designing equipment, such as bins, mixers, and feeders, to ensure efficient and reliable material handling.

Bulk Material Handling: Industries involved in the transportation and storage of bulk materials, including mining, agriculture, manufacturing, and logistics, consider the angle of repose to optimize material flow, prevent blockages, and improve operational efficiency.

Geotechnical Engineering: The angle of repose is essential in geotechnical investigations, especially in assessing the stability of slopes, embankments, and natural landforms. It helps determine the potential for landslides and the safe design of structures on slopes.

Powder Technology: In industries dealing with powdered substances like pharmaceuticals, cosmetics, chemicals, and ceramics, the angle of repose plays a role in characterizing the flowability and handling properties of powders, aiding in process optimization.

Sports and Recreation: The angle of repose is considered in designing ski slopes, snowboarding parks, and BMX tracks. It helps determine the appropriate slope gradients for safe and enjoyable recreational activities.

These are just a few examples, and the angle of repose can be relevant in many other sectors where granular materials or bulk solids are involved in handling, transportation, or storage.